Commercial and institutional restrooms have a measurable impact on certification outcomes under LEED and WELL. Water efficiency, hygiene, accessibility, and durability converge at the fixture level—where ADA requirements, CALGreen mandates, EPA WaterSense labeling, and ASME standards directly shape design and specification.

This article outlines how architects and engineers can specify restroom fixtures that satisfy technical codes and contribute meaningfully to LEED and WELL pathways, without relying on marketing language or vendor positioning.

Certification Schemes Applicable to WC/Urinal Fittings

Overview of LEED: Water Efficiency Emphasis

LEED, administered by the U.S. Green Building Council, places restroom fixtures at the core of the Indoor Water Use Reduction prerequisite and associated Water Efficiency credits.

Information on the LEED program includes

LEED Program – USGBC

Key requirements include:

- Baseline flow/flush rates (e.g., 1.6 gpf water closets, 1.0 gpf urinals, 0.5 gpm public lavatory faucets).

- Minimum 20% water-use reduction from the LEED baseline.

- WaterSense labeling for all eligible new toilets, urinals, private lavatory faucets, and showerheads (where applicable).

WELL BUILDING STANDARD OVERVIEW

WELL, administered by the International WELL Building Institute, focuses on hygiene, accessibility, and user comfort rather than strict efficiency thresholds.

WELL Programm Information:

Web: WELL Certified

Web address: WELL Standard

Relevant WELL features emphasize:

- High-quality, reliable handwashing fixtures

- Contactless or low-contact actuation

- hygiene-supportive layouts and fixture placement

- Management of water quality and material compatibility

Regulatory and Code Context

ADA Accessibility Requirements

The 2010 ADA Standards for Accessible Design establish mandatory dimensional and operational criteria for restroom fixtures.

ADA Standards:

accessed at ADA 2010 Standards

Key fixture-related provisions:

- Lavatory rim/counter height ≤ 34 in above finished floor

- 30 × 48 in clear floor space for a forward approach

- Knee/toe clearances under lavatories; insulation of pipes

- Operable parts usable with one hand and without tight grasping/twisting

- Proper placement of the accessories-soap, towels, and toilet tissue-within reach ranges

CALGreen Water Efficiency Requirements

CALGreen, Title 24 Part 11, is a mandatory green code with prescriptive water-use requirements.

CALGreen Overview:

CALGreen – CA.gov

Common non-residential limits:

- Toilets: ≤ 1.28 gpf

- Urinals: ≤ 0.5 gpf

- Lavatory faucets: ≤ 1.5 gpm

- Showerheads: ≤ 2.0 gpm

CALGreen also incorporates WaterSense labeling and performance pathways for demonstrating ≥20% aggregate indoor water-use reduction.

WaterSense and Plumbing Performance Standards

EPA WaterSense Program

EPA’s WaterSense program defines both efficiency and performance criteria for restroom fixtures.

WaterSense home:

EPA WaterSense

Product Specification:

WaterSense Product Specifications

WaterSense-labeled products:

WaterSense Products

Explanatory note of the WaterSense label:

About the WaterSense Label

Typical WaterSense limits:

- Toilets (flushometer-valve type) ≤ 1.28 gpf

- Lavatory faucets: ≤ 1.5 gpm at 60 psi

WaterSense also includes detailed performance testing—particularly important in high-traffic environments.

ASME Codes for Life and Safety

The major standard controlling faucet and valve performance is:

ASME A112.18.1/CSA B125.1 – Plumbing Supply Fittings:

ASME A112.18.1 Standard

ASME standards ensure:

- Mechanical durability during cyclic loading

- Resistance to pressure/temperature

- Material Safety and Performance Consistency

For Division 22 specification, ASME compliance is often required in tandem with WaterSense and local code thresholds.

Restroom Fixture Integration and LEED Requirements

Indoor Water Use Reduction

To meet the water use requirements in LEED,

- Set the baseline using the default rates in LEED.

- Document fixture rates from the design case specification schedule.

- Show at least 20% total savings for all covered luminaires.

- Ensure all applicable fixtures are WaterSense labeled where required.

Common design activities include:

- Using ≤1.28 gpf toilets and ≤0.5 gpf urinals

- Specification of public restroom faucets of 0.5 gpm where possible

- save useless faucets run times by the use of metering or sensor faucets

Metering and system integration

However, sub-metering and ongoing monitoring are incentivised by LEED.

This often involves:

- Sub-metering of domestic water in restroom branches

- Integration of pulse-output or digital metering with BAS/BMS

- Networked valves or faucets for diagnostics and leak detection

WELL Requirement and Restroom Fixture Integration

WELL’s hygiene-based approach identifies:

- Touchless fixtures that reduce disease transmission

- Sufficient faucet run times to enable proper hand-washing of 20–30 seconds ideally

- Proper placement of soap and drying fixtures within ADA reach

- Material resistance to frequent disinfection processes

Layouts should avoid:

- Objects protruding into circulation paths

- Sensor locations that are hard to reach from seated/wheelchair position

ADA-Compliant, Certification-Ready Restroom Layouts

Restrooms and Sinks

Align ADA with LEED/WELL by:

- Maintain lavatory height ≤ 34 in

- provide the necessary knee and toe clearances

- Specify insulated piping below lavatories

- Use reachable operable controls sensor or lever-style

- Ensure sensors trigger predictably from accessible locations

Toilets, Urinals & Accessories

design teams for:

- Location of toilet centerline and compartment clearances

- Grab bar locations and heights

- Toiletpaper dispenser location, 7–9 in ahead of WC centerline

- Reach ranges for flush valves, soap, dryer, towel and waste stations

Combo of CALGreen, LEED, and WELL

A typical combined compliance strategy would include:

- Meet the limits of CALGreen code: 1.28 gpf WC, 0.5 gpf urinal, 1.5 gpm lav faucet.

- Perform LEED reductions through modeling design-case fixtures versus baseline.

- Specify WaterSense fixtures that will meet LEED WaterSense standards.

- Satisfy WELL by adding touchless fixtures, durable materials, and hygienic placement.

This integrated approach avoids conflicts between code, efficiency, and hygiene objectives.

Durability and System Integration Considerations

Durability for High-Traffic Applications

Commercial restrooms serving airports, campuses, stadiums, health care:

- ASME-specification valves and fittings

- Vandal-resistant aerators, handles, and sensor windows

- Materials compatible with chemical disinfection

- Serviceable access to filters, strainers, and cartridges

Without durability-focused specifications, water-saving components may degrade, compromising LEED outcomes.

Telemetry and Operational Visibility of BMS/BAS

Modern fixtures may support:

- Event logging (activations, flush counts)

- Continuous flow/leak alerts

- Trend reporting on water-use optimization

These capabilities support both LEED metering credits and WELL’s continuous performance requirements.

Practical Specification Guidelines

Toilets and Urinals

- Toilets: ≤ 1.28 gpf

- Urinals: ≤ 0.5 gpf

- Require WaterSense labeling where available

- Use sensor flush valves with manual overrides

- Ensure ADA reach ranges for controls

Bathroom Faucets

- Public toilet faucets: 0.5 gpm where acceptable, otherwise ≤1.5 gpm

- Shall conform to ASME A112.18.1/CSA B125.1

- Prefer contactless operation with real windows of re-activation

Showers – associated with lockers or employees’ areas

- Flow rate ≤ 2.0 gpm

- Couple with thermostatic/pressure-balancing valves

- Ensure controls that are ADA-compliant and grab bars where required

Accessibility and User Interface

- Place all controls within ADA reach ranges

- Avoid objects protruding more than 4 in into circulation paths

- Maintain 30 × 48 in. clear floor spaces adjacent to fixtures

LEED and WELL Documentation

Include in submittal requirements:

- Flow/flush rate documentation

- WaterSense certificates

- ASME/CSA compliance statements

- Fixture schedule listing baseline vs. design-case values

Overview

Restroom fixtures influence LEED’s water efficiency metrics, WELL’s hygiene standards, ADA accessibility, CALGreen code compliance, and long-term operational durability.

By specifying fixtures that:

- Meet ADA dimensional and reach requirements

- Comply with CALGreen or other jurisdictional codes

- Carry WaterSense labeling

- Conform to ASME plumbing standards

- Integrate with BAS/BMS for monitoring

architects and engineers can design commercial restrooms that are efficient, resilient, maintainable, and fully aligned with LEED and WELL certification pathways.

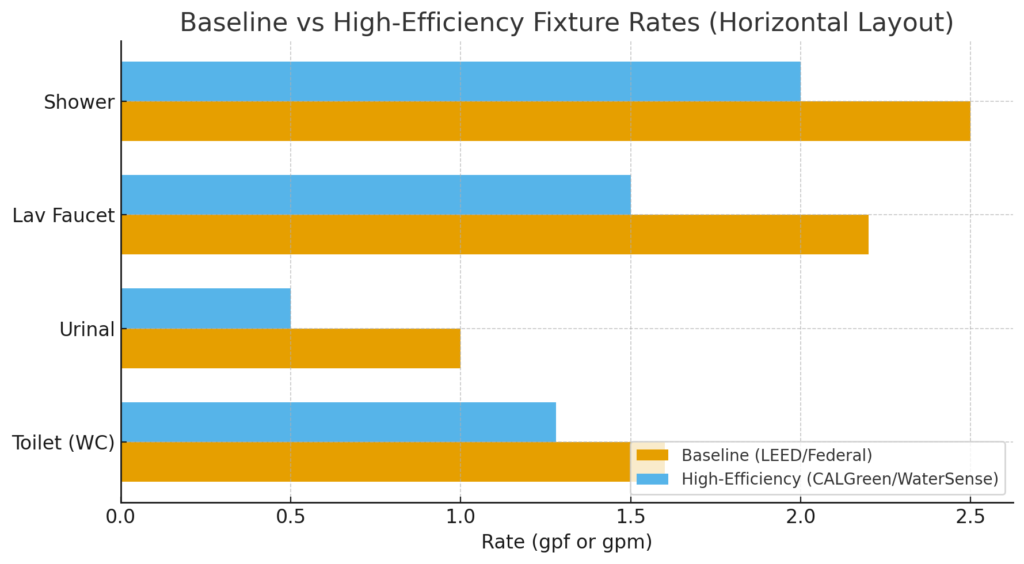

| Fixture Type | Metric (Unit) | Baseline (LEED / Federal) | High-Efficiency Target (CALGreen / WaterSense / Spec) | Notes |

|---|---|---|---|---|

| Toilet (WC) | Flush rate (gpf) | 1.6 gpf | ≤ 1.28 gpf | WaterSense limit; typical CALGreen-compliant WC. |

| Urinal | Flush rate (gpf) | 1.0 gpf | ≤ 0.5 gpf | Common CALGreen and high-efficiency urinal value. |

| Lavatory Faucet (Public) | Flow rate (gpm) | 2.2 gpm (private baseline); 0.5 gpm (public baseline in LEED) | 0.5–1.5 gpm (≤ 1.5 gpm WaterSense) | Many LEED projects use 0.5 gpm for public restrooms. |

| Lavatory Faucet (Private/Staff) | Flow rate (gpm) | 2.2 gpm | ≤ 1.5 gpm | WaterSense lavatory faucet max at 60 psi. |

| Showerhead | Flow rate (gpm) | 2.5 gpm | ≤ 2.0 gpm | Common CALGreen/efficient shower target. |

No responses yet